In a perfect world, there would be a standard tool waiting on the shelf for every machining application. In reality, tooling specifications are so precise and applications so specialized, that there is often no standard tool configured exactly as you need it for optimal performance in the task at hand.

Falcon Group can provide provides a custom-designed, application-specific tool that would be cost effective. Custom cutting tools are typically used in industries such as aerospace, medical, and automotive where precision and specialized cutting requirements are needed.

The process of custom cutting tool engineering typically involves several steps, including:

Although Custom cutting tool engineering can be a complex process, We at Falcon Group with specialized knowledge of cutting tool design, materials science, and manufacturing processes can provide our customers with the optimal solution.

Although Custom cutting tools can be more expensive than standard cutting tools, but they have the advantage of being specifically designed for a specific task, which leads to higher performance, better surface finish, and longer life. They are also very useful when working with exotic materials or when the parts have complex geometries.

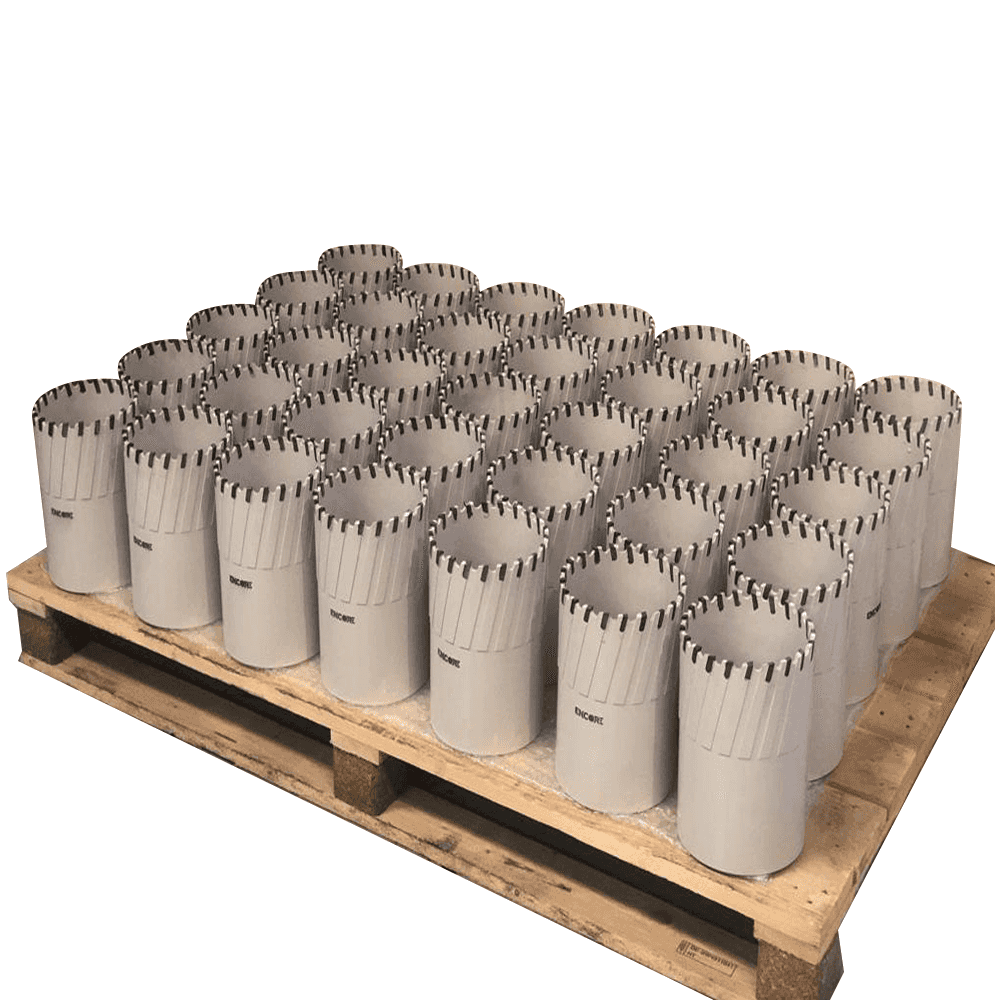

ENCORE® Brazed Tools are designed for high speed, better performance, and higher cutting efficiency. This tool offers high precision, high efficiency, and high reliability. These are available in a wide range of sizes and styles to meet your application requirements. Most importantly these are available at competitive prices.

While providing you with a brazed tool, we create a design for the tool, which includes determining the shape and size of the tool, as well as the specific properties and characteristics it needs to have for the intended application. Each manufactured tool goes through 100% QC check prior to delivery to customers.

A hot tapping cutter is a tool used in the process of hot tapping, which is a method of creating a connection to a pressurized pipeline or vessel while it is still in service. The cutter is used to make a hole in the pipe on vessel, through which a valve or fitting can be installed. The cutter is typically made of high-speed steel or tungsten carbide, and is designed to withstand the high temperatures and pressures of the process. The cutter is typically used in conjunction with a hot tapping pilot drill with coupon retaining wires. ENCORE® is a leading supplier for these cutters and pilot drill to multiple Hot tapping service companies in the region. Tooling manufacturing capabilities for 2” to 78″ in diameter bores in pressurized pipelines, pressure vessels, and tanks.

It is available in a variety of configurations and options to meet customer requirements.

Profile cutting tools are specialized cutting tools that are used to create specific shapes or profiles in a workpiece. These tools are typically used in the manufacturing of parts for a wide range of industries, including aerospace, automotive, and medical equipment. Examples of profile-cutting tools include end mills, routers, and profile grinding wheels. They are used in milling, grinding, and EDM machine.

End mills are rotary cutting tools with multiple flutes and can create a wide range of shapes and profiles. Routers are also used for profile cutting and can be used to create complex shapes and geometries. Profile grinding wheels are used in surface and cylindrical grinding machines to create precise profiles on workpieces.

The choice of profile-cutting tool will depend on the specific requirements of the application, including the material of the workpiece, the required shape or profile, and the desired surface finish. Get in touch with us with your specific requirements and we will provide you a solution

T-slot or dovetail tools are tools used in metalworking and machining to create T-shaped slots or dovetail-shaped slots in a workpiece. These slots are used to hold and secure other parts or components in a machine or tool.

T-slot tools are typically used to create T-shaped slots in a workpiece, and can be in the form of a cutter, router bit or milling machine. These tools are used to make precise cuts in the workpiece, and are often used in the production of industrial machinery and equipment.

Dovetail tools are used to create dovetail-shaped slots or grooves in a workpiece. These tools can be in the form of a cutter, router bit or milling machine. Dovetail slots are commonly used in woodworking and furniture making, such as for creating joints between wooden pieces. They are also used in the manufacturing of machinery and equipment.

ENCORE® tools are extensively tested under the strict supervision of our quality controllers in order to ensure that these products are free from any possible defect. Our products can be modified according to the requirements of our clients.

ENCORE® manufactures Parting tools for Clamshell Pipe cutting machines of any brand. These tools are typically mounted on a pipe cutting machine and rotate at high speeds to cut through the material. They come in a variety of sizes and shapes depending on the material being cut and the desired cut quality.

Beveling tools are used to create angled or beveled edges on the ends of pipes or tubing. They are typically mounted on a pipe cutting machine and rotate at high speeds to remove material and create the desired bevel angle.

There are several types of beveling tools that are commonly used on pipe cutting machines:

Beveling tools are typically made from high-speed steel (HSS) or carbide. They can also be coated with special materials to increase their durability and lifespan.

Splitting saws, also known as slitting saws or slotting saws, are cutting tools that are used to make precise cuts in a variety of materials, including metal, wood, and plastic. They consist of a circular blade with teeth on the edge that rotate at high speeds to cut through the material.

Splitting saws are typically used for cutting slots, grooves, or kerfs in a material, and they can be used in a variety of different applications, such as cutting gears, keyways, and splines, or for creating channels for wiring and plumbing.

ENCORE® can manufacture several types of splitting saws like:

Splitting saws are usually mounted on a machine, such as a milling machine, drill press or a lathe. They can be used in a variety of industries such as metalworking, woodworking, and manufacturing.

Wellhead valve gate cutters are similar to annular cutters or hot tapping cutters are used to cut through the valve in a Wellhead gate valve. When access to the well is lost when the gate gets stuck, or cannot be moved to the open position, these cutters are mounted on to special machines and used to drill through the valve gate. They are typically used along with a Pilot Drill.

Revert to us with your requirements and we assure you the best quality cutters for your wellhead operations.

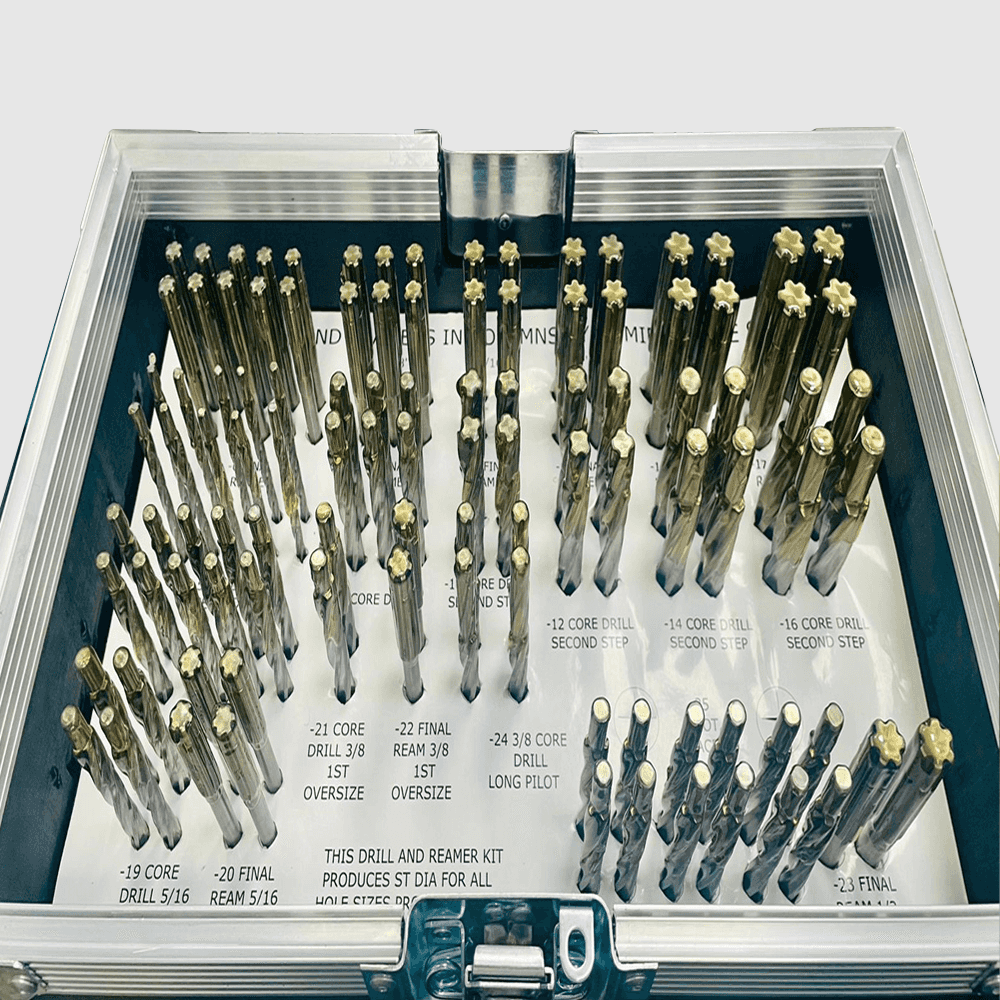

Aerospace cutting tools are specialized tools used in the aerospace industry for cutting and shaping aerospace materials such as metals, composites, and ceramics. These tools include end mills, drills, saws, and routers, which are specifically designed to handle the unique characteristics of aerospace materials and to meet the precise tolerances required in aerospace manufacturing. Aerospace cutting tools also often incorporate advanced features such as coatings to improve their durability and performance in demanding aerospace applications.

ENCORE® offers a range of high-performance, durable, long-life aerospace cutting, and milling tools, these are more cost effective than traditional tools due to their long service life when cutting highly abrasive materials.

ENCORE® milling and cutting tools reduce machine service intervals and loss of valuable production time and material wastage due to tool changes and breakages caused by failure and wear of traditional tools.