These are bearings made specially to withstand axial loads, like those seen in pumps and turbines. To support the load, they are often built with a thicker bearing surface on one side.Thrust bearings are frequently employed in a variety of equipment, including pumps, generators, and compressors, as well as in cars, planes, and large machinery like cranes and excavators. They support the axial load on rotating shafts in gearboxes, turbines, and other power transmission systems.

A form of thrust bearing that uses a set geometry to support and guide axial loads is known as a fixed geometry thrust bearing or a self-acting thrust bearing. They usually consist of a thrust pad and a housing that is intended to support and guide the thrust pad while it is moving.

Heavy machinery, power generation equipment, and aircraft are just a few of the applications for fixed geometry thrust bearings. They are renowned for being able to tolerate fast speeds and having a large load capacity.

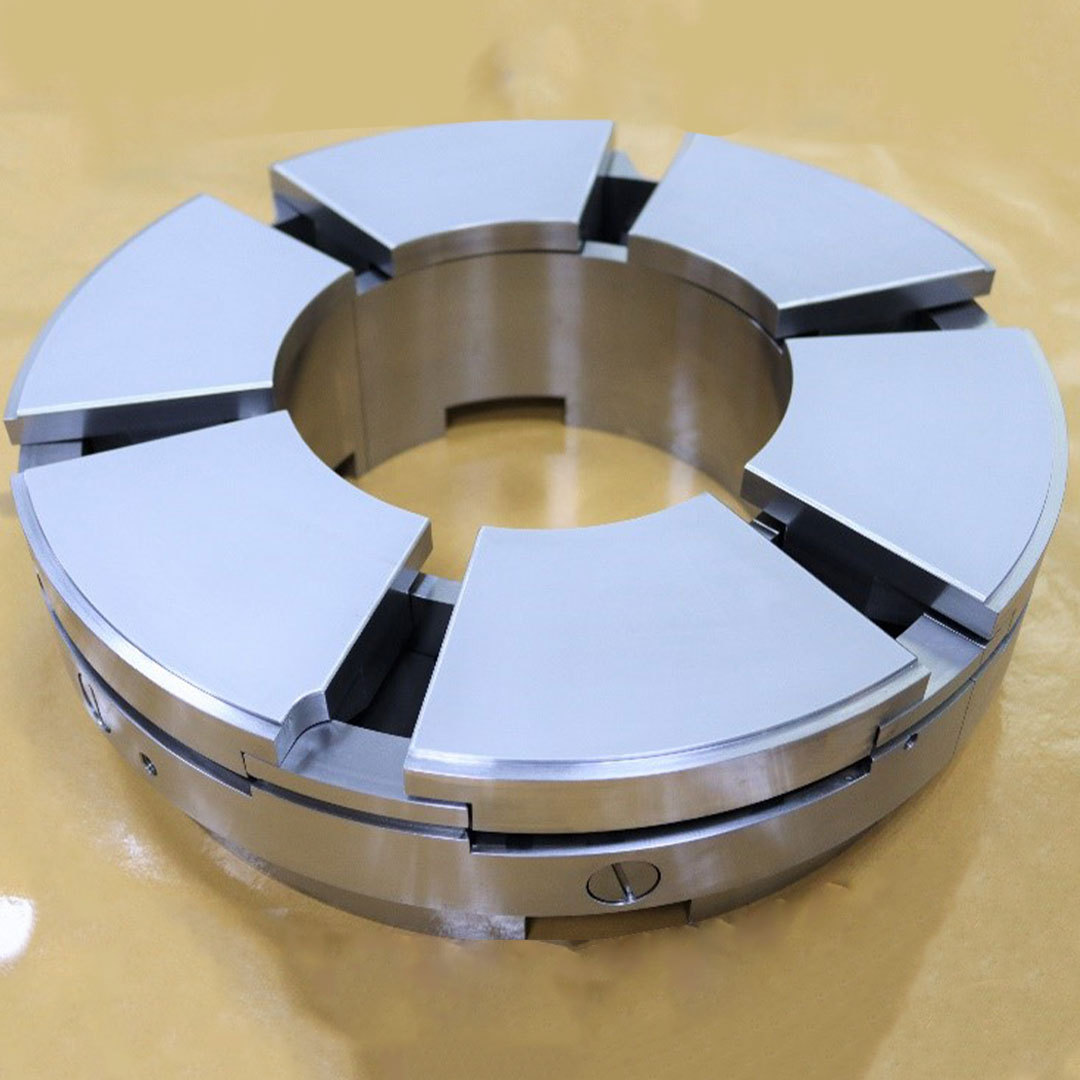

There are various varieties of fixed geometry thrust bearings, such as tilting pad thrust bearings that carry the load using a tilting pad design to distribute it equally throughout the thrust pads and cylindrical thrust bearings that do the same thing but with a cylinder housing and thrust pads.

Compared to other types of thrust bearings, including hydrodynamic bearings, fixed geometry thrust bearings provide a number of advantages. They can handle larger loads and speeds and are often more maintenance-free and robust. They are ineffective, though, in high-temperature applications.

They are a form of mechanical thrust bearing used in rotating machinery such as generators. They consist of a number of circularly-arranged pads, sometimes known as “tilt pads,” that are fixed on a shaft. The pads can accommodate the axial and radial loads that are imparted to the shaft because they can tilt slightly as the shaft rotates. High load capacity, high speed operation, and extremely little friction are all made possible by this design. Generators and other big rotating equipment frequently employ tilt pad thrust bearings because they can handle high thrust loads and offer good stability and vibration damping.

These mechanical thrust bearings, also called hydrodynamic thrust bearings, use pressurised lubricant to form a thin film between the bearing surfaces, separating them, and enabling friction-free, smooth movement. These bearings can take large thrust loads and offer exceptional stability and vibration damping since they are made to automatically respond to the loads placed on the shaft and maintain a constant level of lubrication. Large generators and other heavy machinery frequently employ self-leveling thrust bearings, which are typically chosen over other types of thrust bearings due to their capacity to withstand huge loads and high speeds as well as their capacity to self-adjust for optimum performance.

A thrust bearing that is actively supporting the machinery or equipment it is installed in while also carrying a load is called an active thrust bearing. The load is actively being moved from one piece of machinery or equipment to another.

In a variety of applications, including turbines, pumps, compressors, gearboxes, and other pieces of machinery and equipment, active thrust bearings are frequently utilised. They can withstand high speeds, radial loads, and misalignments and are made to support axial loads (loads that act in a direction perpendicular to the axis of rotation).

The active thrust bearing is made to function in a variety of circumstances, including loads, speeds, temperatures, lubrication, and other factors. The precise application and the loads, speeds, and misalignments that the bearing must accommodate will determine the thrust bearing to be used.

It’s crucial to remember that the active thrust bearing will experience wear and tear over time, necessitating routine maintenance and replacement to keep it in good working order.

It is a thrust bearing that is not actively supporting the machinery or equipment it is installed in or currently carrying a load. It could be at rest or acting as a redundant or backup bearing in case the active thrust bearing fails.

In important applications where a failure of the active thrust bearing could result in considerable damage or downtime, inactive thrust bearings are frequently employed as a backup or redundant bearing. The dormant bearing can be utilised as a backup during times of high load in applications where the demands on the bearing are intermittent or cyclical.

The requirements for inactive thrust bearings are normally the same as those for active thrust bearings, and they may support the same loads and speeds. However, they might be exposed to various factors, such as temperature, lubrication, vibration, and other characteristics, as opposed to the active thrust bearing.

It’s crucial to keep in mind that even if an inactive thrust bearing isn’t carrying any weight, it still has to be maintained on a regular basis to make sure it’s in good shape and prepared to sustain the weight in the event that an active thrust bearing fails.