These bearings are made to withstand radial loads like those found in spindles and shafts. They serve to lessen friction and wear and typically consist of a cylindrical bearing surface that encircles the shaft. The bearing supports the shaft, lowers friction, and permits free rotation of the shaft.

It is a form of bearing that supports a rotating shaft using a cylindrical metal shaft and an encircling metal housing, also known as a bearing housing or bearing shell. A thin layer of lubricant, such as oil or grease, supports the shaft, which is normally composed of steel or another metal and keeps it apart from the bearing housing. This kind of bearing is a popular option for a variety of applications since it is straightforward in design and reasonably affordable to produce. Plain journal bearings are frequently used in industrial machinery including pumps, compressors, and generators because they are appropriate for low to moderate speed applications and moderate to heavy loads. They are frequently used in vehicles as well as several pieces of machinery and equipment employed in the mining, construction, and agriculture sectors. In general, plain journal bearings are an easy, dependable, and affordable solution for a variety of mechanical and industrial applications.

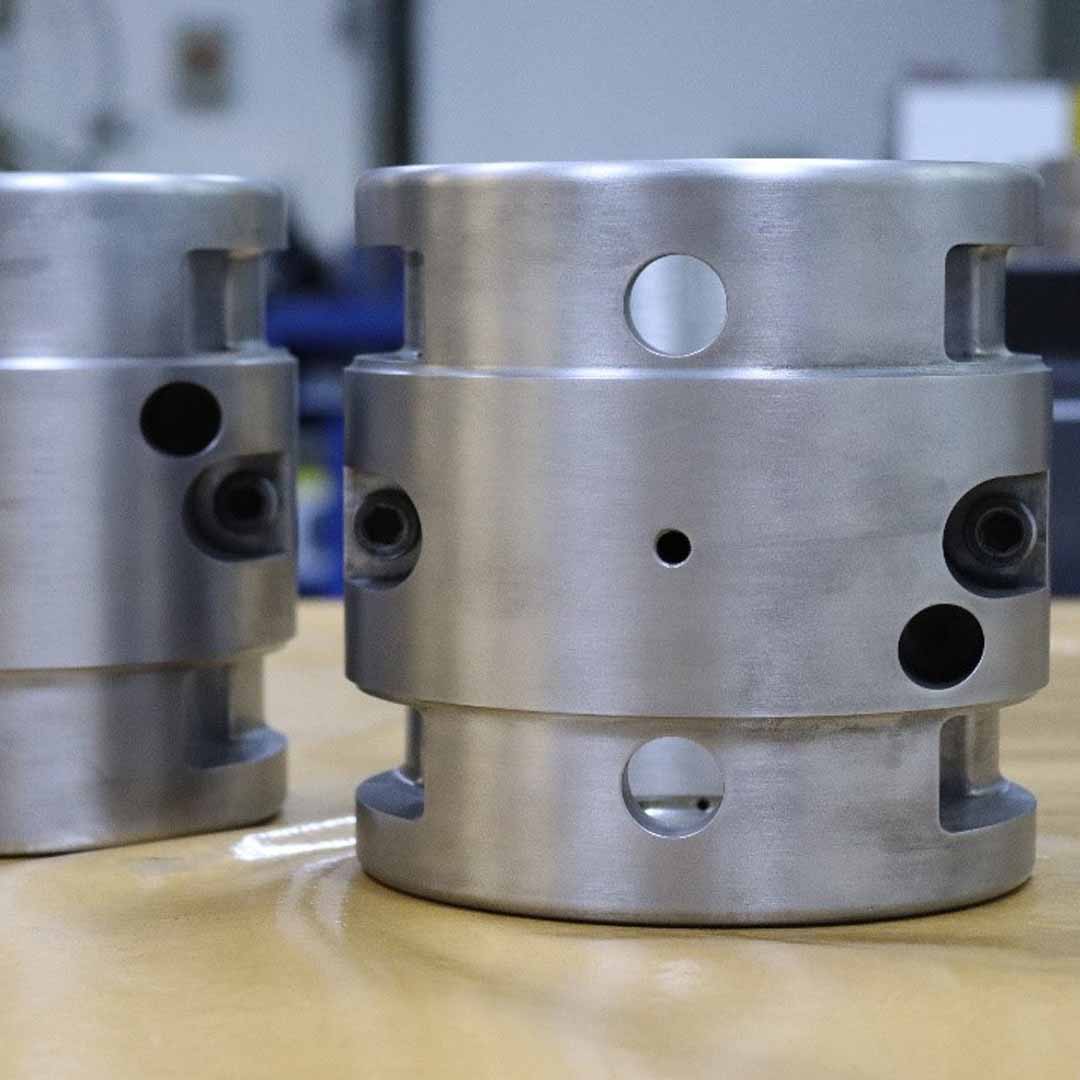

This type of bearing uses a number of lobes, or pads, to support a rotating shaft. These bearings are designed to carry heavy loads with less friction and minimal shaft wear. Powerful industrial machinery like pumps, compressors, and generators commonly contain them.The distribution of several cylindrical journals all the way around the diameter of the main shaft is a distinguishing characteristic of multi-lobe journal bearings. This design’s enhanced stability and load dispersion reduce the possibility of bearing failure.The lubricant can flow through the spaces between the bearing’s lobes, which are normally constructed of a sturdy material like steel or bronze, allowing the lubricant to cool the bearing.These bearings are also used in high-speed applications because the design of multi-lobe bearings reduces the centrifugal forces that are exerted on the bearings and shafts during rotation.Overall, Multi-lobe journal bearings are suitable for high-speed, high-load and high-temperature applications where conventional bearings fail to deliver.

It is a kind of bearing that supports and directs the rotation of moving elements in machinery and equipment. It typically consists of a cylindrical inner surface (the “journal”) and an outer surface with an elliptical shape (the “bore”). The bore’s “lemon” shape is intended to give the journal more stability and support, which lowers wear and friction and enhances the bearing’s overall performance.

It is a specific kind of bearing made for supporting and directing the rotation of rotating components in machinery and equipment. It typically has a flat outer surface and a spherical interior surface (the “journal”) (the “pad”). Greater mobility is possible thanks to the journal’s spherical shape, which can also accommodate misalignment and heavy radial stresses. The pad serves to support and guide the journal and is often housed in a housing. The journal bearing pad’s spherical shape can aid to improve the bearing’s overall performance by lowering wear and friction.

It is a kind of journal bearing where the journal’s and the bearing’s centres are offset from one another. The journal and bearing’s misalignment with respect to the same axis causes this offset. This kind of bearing is frequently employed in situations where the journal must rotate in a certain direction or to compensate for misalignment in the machinery or equipment. Converse offset journal bearings can enhance the bearing’s overall performance by lowering wear and friction.

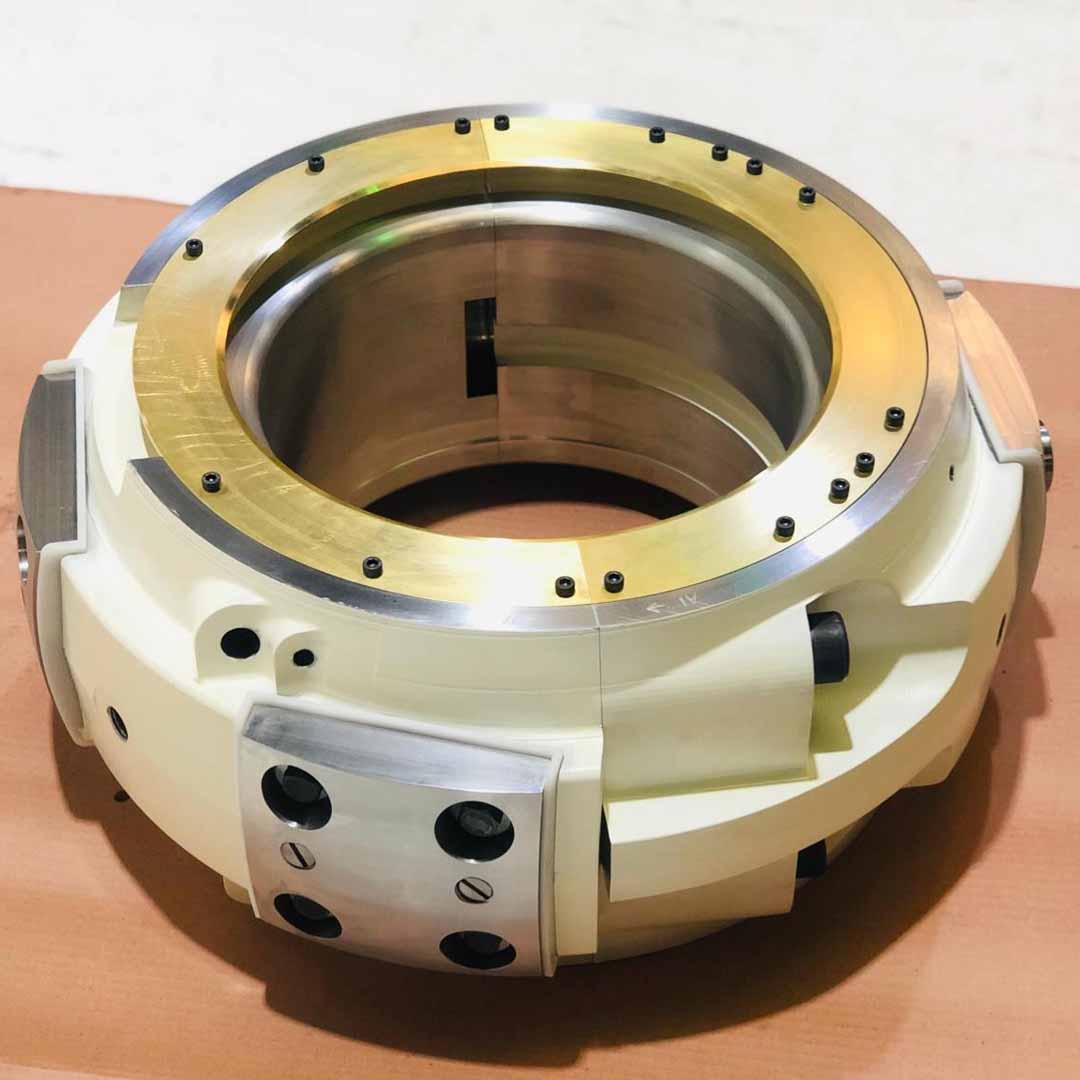

In a variety of industrial and commercial applications, rotating shafts are supported by this type of hydrodynamic bearing. They are made up of a string of “tilt pads” that may tilt or rotate freely along a central axis and are spaced apart by tiny clearance gaps. The pads are normally constructed from a tough, long-lasting material, such steel or ceramic, and are meant to be self-aligning, able to withstand heavy loads, and misalignments.The formation of a hydrodynamic lubricating film between the bearing surface and the shaft underlies the operation of tilt pad journal bearings. To do this, a tiny amount of lubricant, such oil, is injected into the space between the pad and the shaft. The lubricant is pulled into the gap and forms a stable lubrication film when the shaft rotates due to the pressure differential created. Between the shaft and the bearing, this film creates a low-friction, wear-resistant barrier that enables the shaft to revolve smoothly and with little wear.

The rotor shaft is supported by this sort of bearing, which also offers a stable and stable rotation, in generators. Because electrical current might cause arcing and harm to the bearing and the generator, these bearings are made to be isolated. Fiberglass and ceramic are common insulation materials because they are effective electrical insulators.Typically, high voltage generators like those found in power plants and wind turbines use insulated generator journal bearings. They are frequently used in generators as well since the insulation helps keep EMI from impairing the generator’s operation in environments with high electromagnetic interference (EMI).Insulated generator journal bearings’ key benefit is that they help shield the generator from electrical harm, which can increase the generator’s dependability and lengthen its useful life. By minimising the amount of energy lost to electrical resistance, insulated journal bearings can also aid in increasing the generator’s efficiency.Because they need unique materials and manufacturing techniques, insulated generator journal bearings are often more expensive than normal journal bearings. To make sure the insulation is still intact and functional, they also need to be regularly inspected and maintained.